Pick Strategy in Fresh Produce

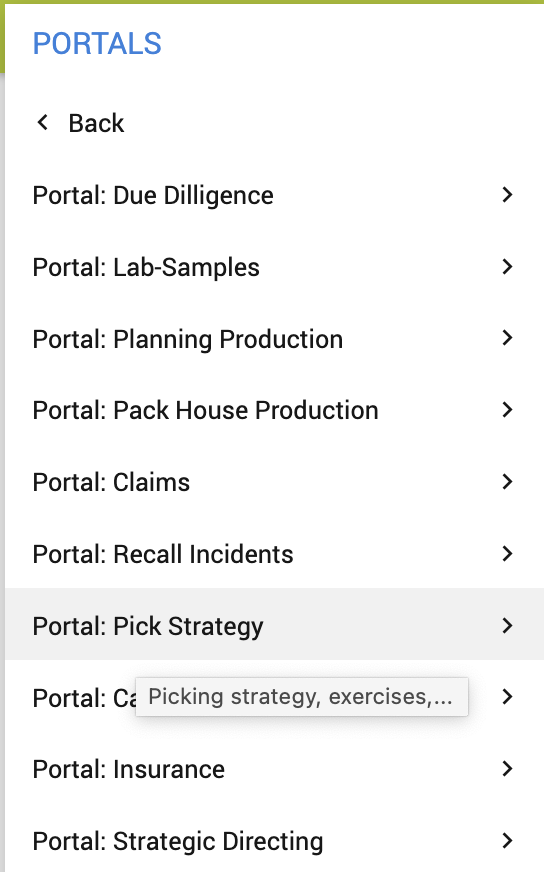

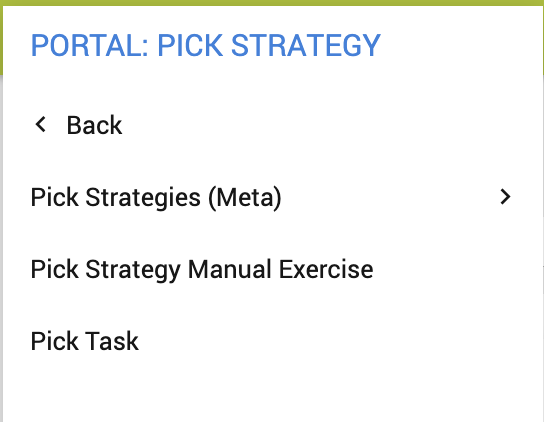

In Flex2B, the pick strategy elements can be found through the 'Portal: Pick Strategy' menu.

Designing an effective pick strategy is crucial for optimizing a supply chain, as it directly impacts order fulfillment, operational efficiency, and customer satisfaction.

Flex2B Cloud has a portal section that is helping you to define certain 'Pick Suggestions' and 'Pick Strategies'.

There are some key considerations and strategies for an efficient fresh produce supply chain picking process:

A,B,C Analysis:

- Classify products based on their importance and demand. Use the ABC analysis (A-items are high-value and high-demand, B-items are moderate, and C-items are low-value and low-demand).

- For Fresh Produce, similar characteristics may put other properties to the A, B, C-items, such as Produce Risk, PPS (the sliding time window in Flex2B and many more...). For each business the A,B, C categories can be defined to their own needs.

- Allocate more resources and efficient picking methods for high-priority items.

Batch Picking:

- Group orders together and pick items for multiple orders simultaneously to reduce travel time.

- Batch picking is particularly effective for orders with common SKUs.

Zone Picking:

- Divide the warehouse into zones, ie Cooling Rools and assign specific pickers to each zone.

- Each picker is responsible for picking items only within their designated zone, reducing travel time.

Wave Picking:

- Combine multiple orders into waves based on common characteristics (ie delivery location, product type).

- Pickers work through waves, improving efficiency by reducing the need to revisit the same location multiple times.

Cross-Docking:

- Directly transfer goods from inbound to outbound without the need for storage.

- Reduces the time products spend in the warehouse and minimizes handling. (ie Replenishment)

Automation and Robotics:

- Implement automated picking systems and robotics for repetitive and high-volume tasks.

- Reduces labor costs and increases speed and accuracy.

Dynamic Slotting:

- Regularly review and adjust item placement based on demand patterns.

- Keep frequently picked items in easily accessible locations.

Pick Accuracy Measures:

- Implement quality control measures to ensure accurate picking.

- Use barcode scanners and RFID technology to reduce picking errors.

Flexible Workforce:

- Cross-train employees to perform multiple tasks within the warehouse.

- This allows for flexibility during peak seasons or unexpected changes in demand.

Continuous Improvement:

- Regularly analyze data and key performance indicators (KPIs) to identify areas for improvement.

- Seek feedback from warehouse staff for insights into potential enhancements.

Seasonal Adjustments:

- Anticipate and plan for changes in demand during peak seasons.

- Adjust staffing levels, storage configurations, and picking strategies accordingly.

Remember, the most effective pick strategy often involves a combination of these approaches, tailored to the specific characteristics and demands of your supply chain. Regularly review and refine your strategy to adapt to changing business conditions and technological advancements.