Segregation flow

Flex²B: Segregation Flow

These flows can be used to issue stock units for segregation or the enforce a quality inspection.

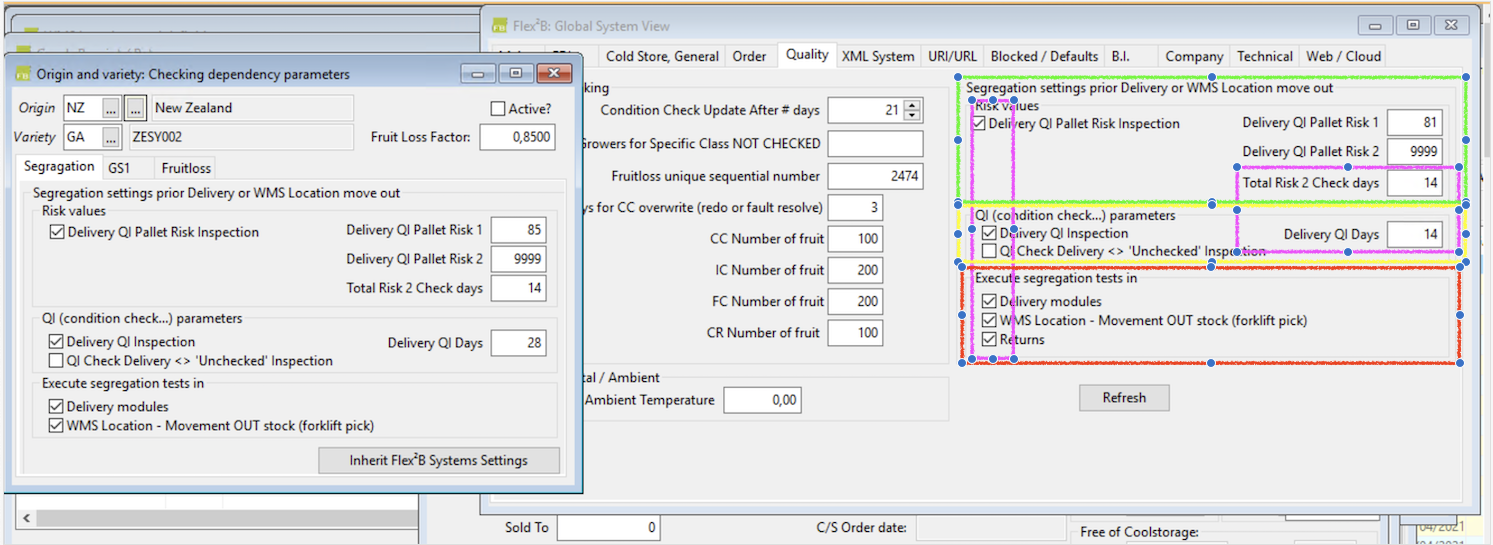

We have a set of global quality segregation triggers , but also a more in depth specific trigger that is relying on a Variety / Origin combination.

These segregation parameters are evaluated on the rest services for the PDA. (Forklift movements, returns, delivery).

.

Below a sample segregation flow (pseudo-language):

Segregation: function module: shouldSegregateFunctions.pkg

Step 0 - initialisation

if (delivQIInspection) -> execute true to bcheckonCC

if (delivQIPalletRiskInspection) -> execute true to bcheckOnRisks

if (pallet.location settings WMS###-field) has a isSegregationCheckExcluded setting true (WMSLocat.ExcludeFromSegregationTest = 'X'), then the segregation evaluation is NOT executed. (looking at the data in ZEE, I see that the WMS locations for ASS-Tables & OMNIPACK coolcell-ids have this setting to True, real ZEE locations do not)

Steps segregation

if (pallet.DelivQIInspection or pallet.DelivQIInspection) -> explicit flagged for segregation - You can use this flags to execute explicit segregation ('X' for a True value) -> segregate

if (pallet.CCFlag, Pallet.IntercheckFlag or pallet.Speedcheckflag = 'X') -> Move true to bPalletCheckingIndicated

... and if (checkonCC AND bPalletCheckingIndicated) AND Pallet.StorageCat = 'U') -> segregate

if (bcheckOnRisks AND Pallet.PalletRisk > DelivQIPalletRisk1 ) AND Pallet.StorageCat = 'U') -> segregate

if (bcheckOnRisks AND Pallet.PalletRisk > DelivQIPalletRisk2 ) AND (today - Pallet.DateLastChecked > cssys.TotRisk2CheckDays ) -> segregate

If (CSSYS.DelivQIUncheckInspection = True)

... and bCheckOnCC AND Pallet.StorageCat = 'U' AND ( today - Pallet.DateLastChecked) > cssys.delivQIDays -> segregate

If ( bCheckOnCC and (Pallet.DateLastChecked = '') and (bPalletCheckingIndicated ) ) -> segregate

This is executed on the global in combination with a stricter that might be defined in Origin/Variety

Where:

- Global Systems view

- Origin & Variety: checking dependency parameters

General note: an additional parameter for Pallet risks segregation exclusion, is implemented. It allows you to control the segregations based around a Pallet Risk for those Materials that are currently included in an open Delivery.

The below screenshots have a similar component in the Web/Cloud application.

Red Block:flow to execute segregation testing. (Resp Delivery, Forklift Movements en Returns)

Green block: all risk parameters

Yellow block: QI (aka CC/IC/SC/SA)

- Origin/Variety might have a stronger spec per combination.

- When one fails, the segregation will be indicated to the F/L driver

- Should segregate is evaluated on the PDA in the Delivery-interface, Vessel discharge, forklift-pick operations and Goods Receipts (inwards, CSSYS.CheckingPriorReturn = true all type of GoodsReceipts).