Produce operations

Produce Operations

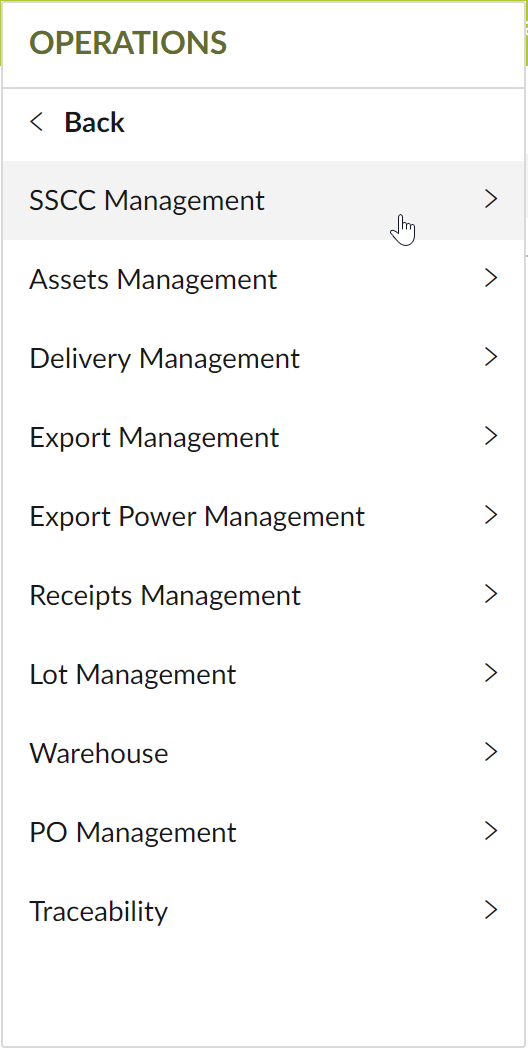

- Operations

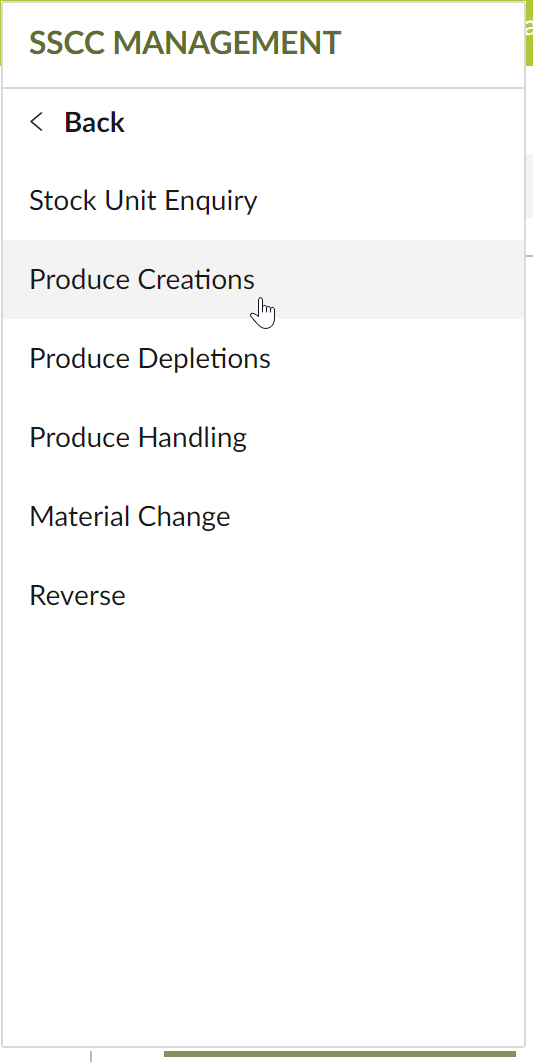

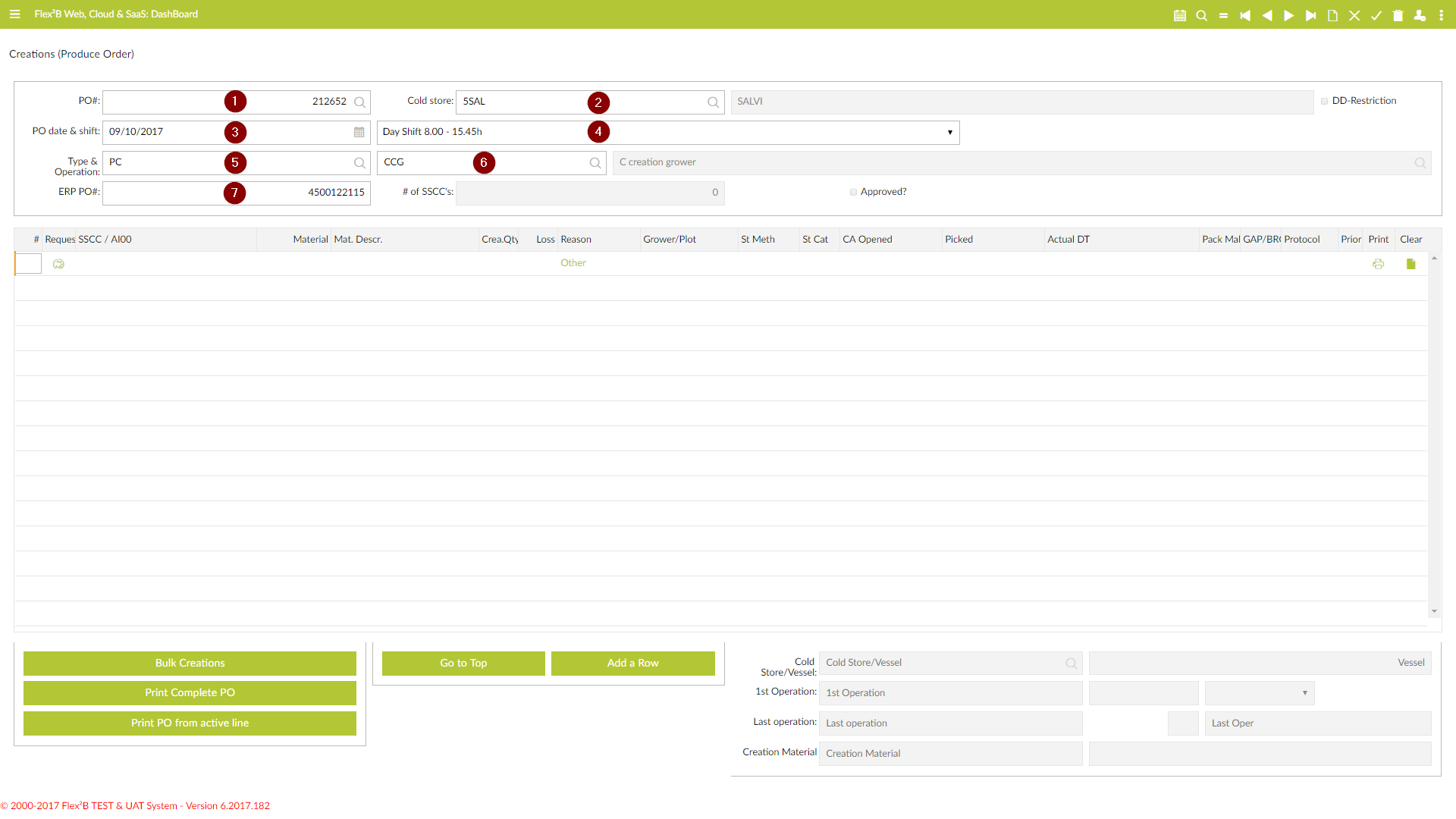

From the operations menu select ‘SSCC Management, ‘Produce Creations’

Process are used by the supplier to generate packed inventory generally received in response to a demand from Flex²B-Dossier market. Inventory data for product that has been produced but not allocated to a demand is also received i.e. where the supplier has excess capacity and is packaging to inventory in anticipation of the next weeks.

Visibility of available packed inventory is important for monitoring how the production process is progressing against the demand and for creating purchase orders and delivery instructions for loadout.

To generate packed inventory

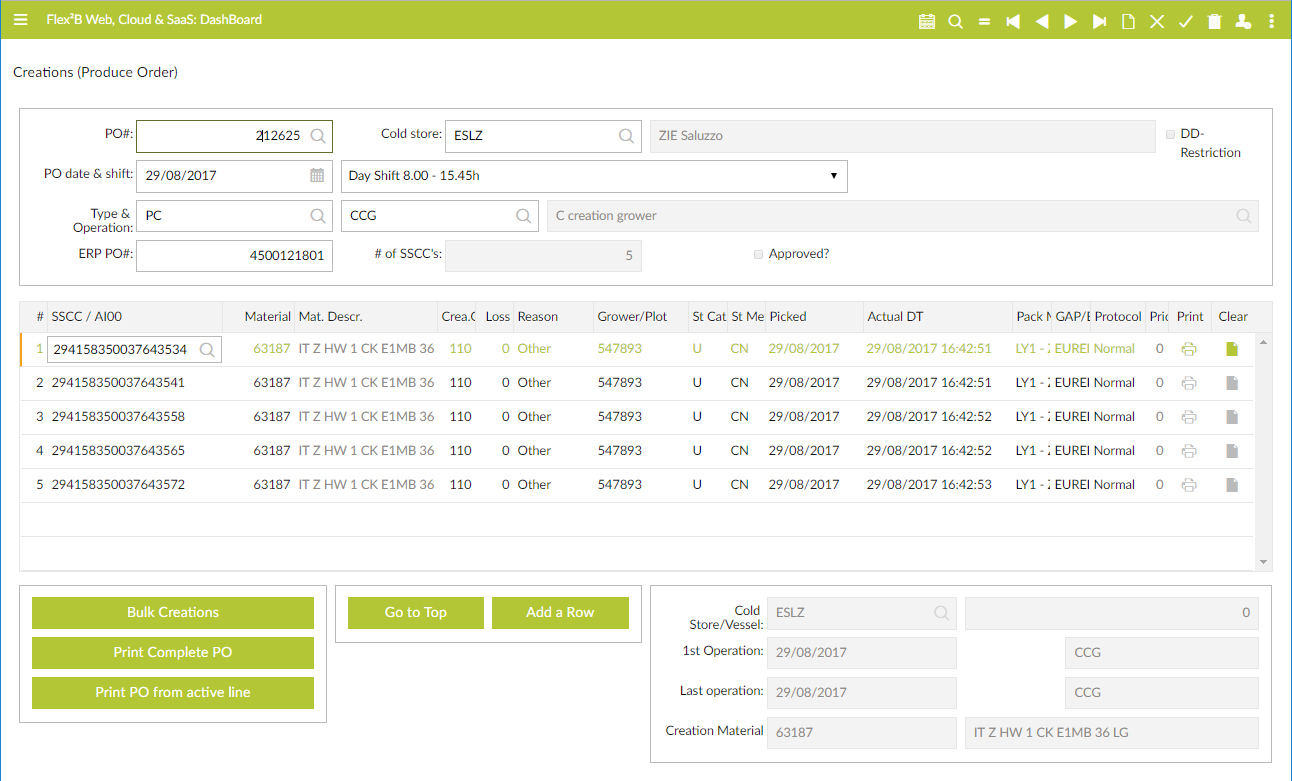

- PO# number will be given automatically after save of the header

- Cold Store field, defines the packhouse (plant/storage location) inventory is created for, Prompt list available, mandatory

- Date field default to today, mandatory

- Shift field efault to day shift, mandatory

- Type field ‘PC’, i.e. pallet creation, mandatory

- Operation type field “CCG”, i.e. creation of grower related inventory, is mandatory

- Erp Po# field, related to Flex²B-Dossier demand SAP Po#, not mandatory

Before entering the detail grid, we must make sure that the current check header record is valid, all mandatory fields are filled in and saved. If it is not, do not allow entry into the grid.

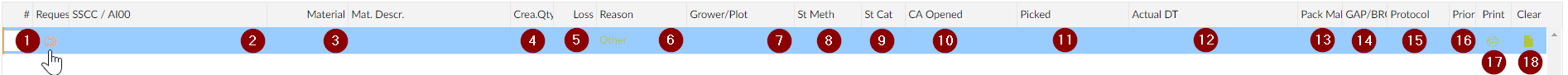

- Generate one by one pallet

- Request icon

, mouse click will generate a unique SSCC pallet number

, mouse click will generate a unique SSCC pallet number - SSCC pallet number, mandatory

- Material number, restricted by packhouse, related to material or Brand/Origin/Variety (master data), mandatory, decription will populated automatically.

- Number of packs, defaulted to maximum number of packs, mandatory

- Fruitloss, 0

- Reason Code for operation done, default ‘other’, mandatory

- Grower code, mandatory

- Storage method, default ‘CN’, mandatory

- Storage source defines quality of fruit, ie. default to ‘U’, unchecked.

- CA opened, if storage method is ’CA’, i.e. controlled atmosphere, CA date mandatory when opened

- Pick date, default ‘today’ when fruit picked, mandatory

- Actual DT, default ‘today HH:MM:SS’, mandatory

- Pack Make, mandatory

- Protocol, ex. Europe gap complent, mandatory

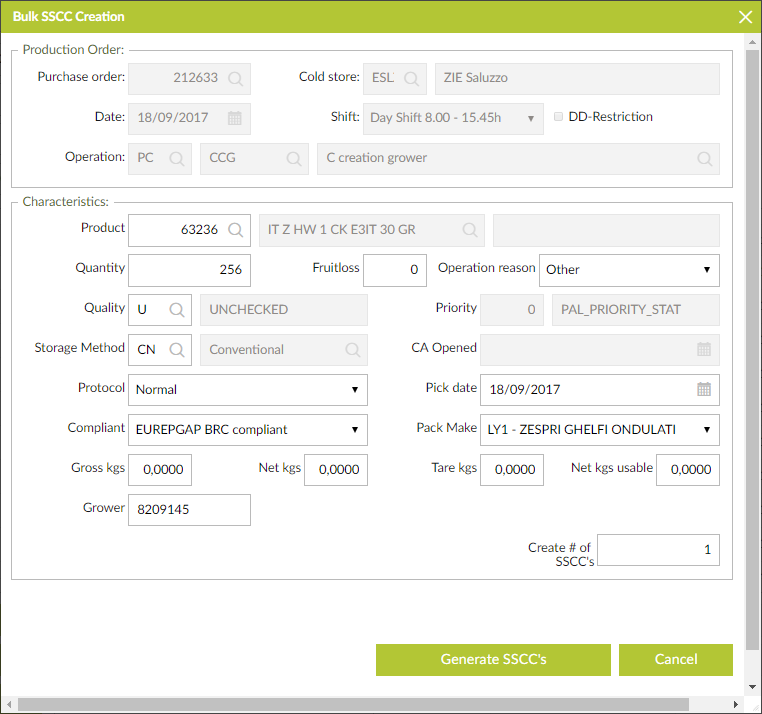

- Push <Bulk Creation> button to generate more than one pallet @ the same time

- Material number, restricted by packhouse, related to material or Brand/Origin/Variety (master data), mandatory

- Number of packs, defaulted to maximum number of packs, mandatory

- Fruitloss

- Reason Code for operation done, defaulted to Other, mandatory

- Storage source defines quality of fruit, ie. default to ‘U’, unchecked.

- Storage method, mandatory

- CA opened, if storage method is ’CA’, i.e. controlled atmosphere, CA date mandatory when opened

- Protocol, default to ‘N’

- Pick date, when fruit picked, mandatory

- Compliant, ex. Europe gap compliant, mandatory

- Pack Make, mandatory

- Gross, Net,Tare & Net usable kg

- Grower code, mandatory

- Create # of pallets

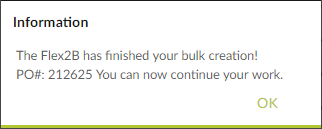

Push Generate SSCC’s button to generate stock

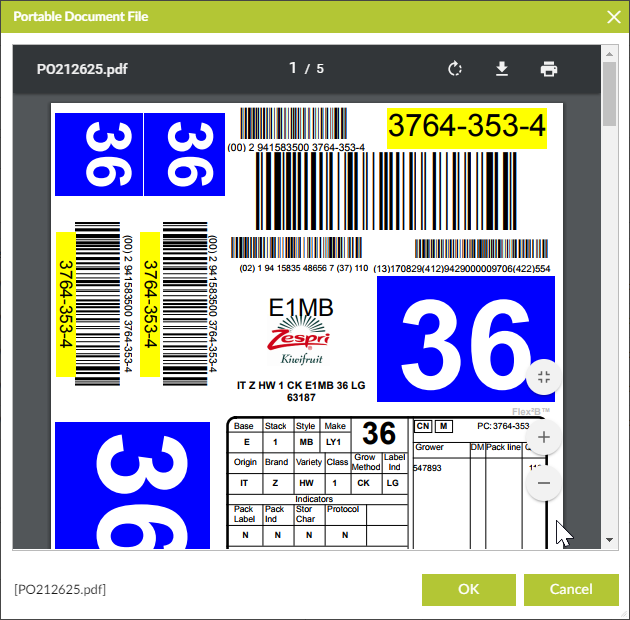

Push Print complete PO to generate pallet cards.

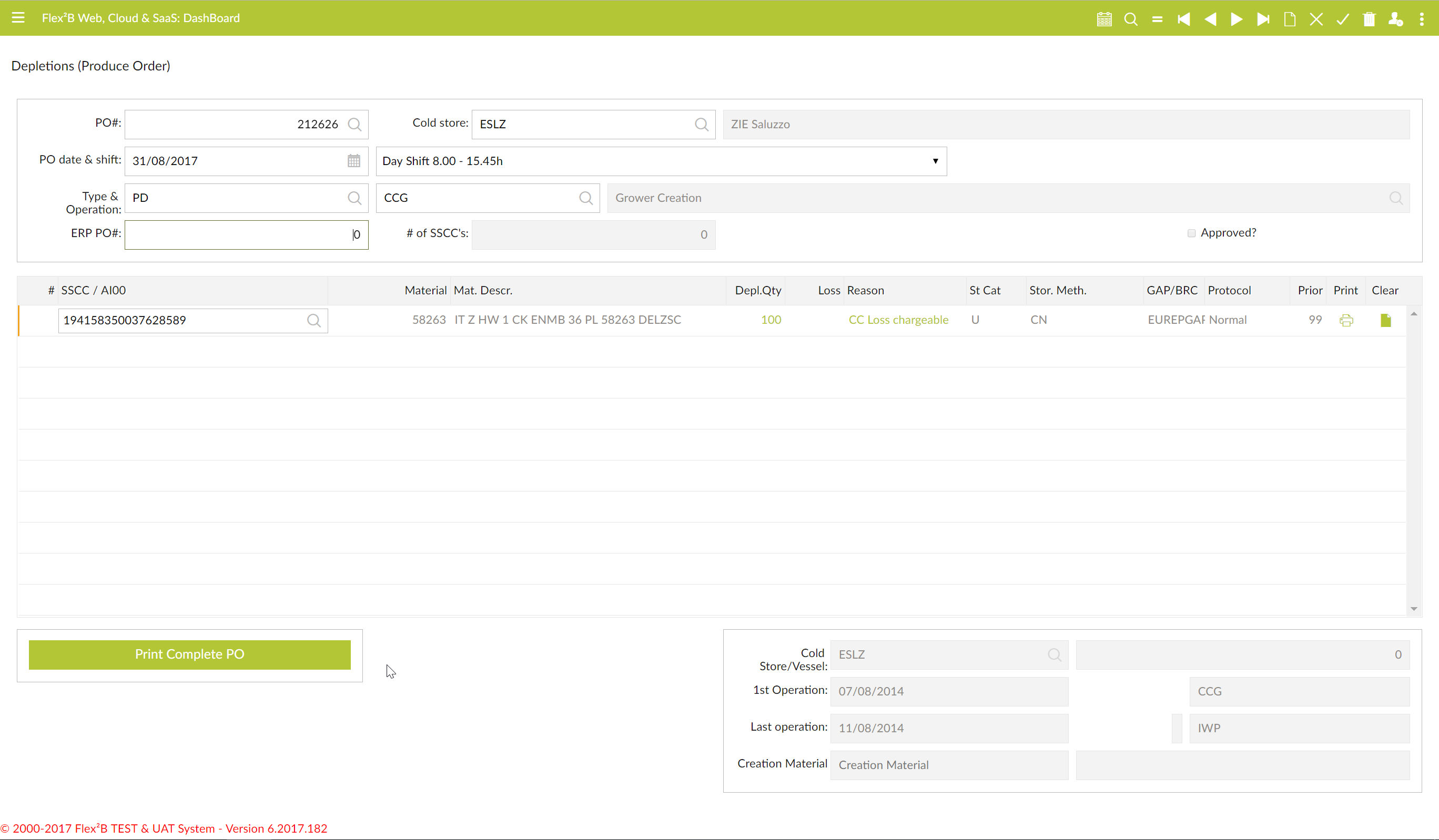

From the operations menu select ‘SSCC Management, ‘Produce Depletions’

- Fill in the PO,

- Cold Store : ‘ZCRD’

- type and operation ‘PD’ ‘DGP’